The difference between Glycerine filled manometer and silicone-filled pressure gauge

As we all know, vibration, pulsation, and pressure peaks are the most common causes of pressure gauge performance degradation and failure. In today's more demanding environment, instruments in the oil, gas, and chemical industries and processing plants must work under such harsh conditions every day.

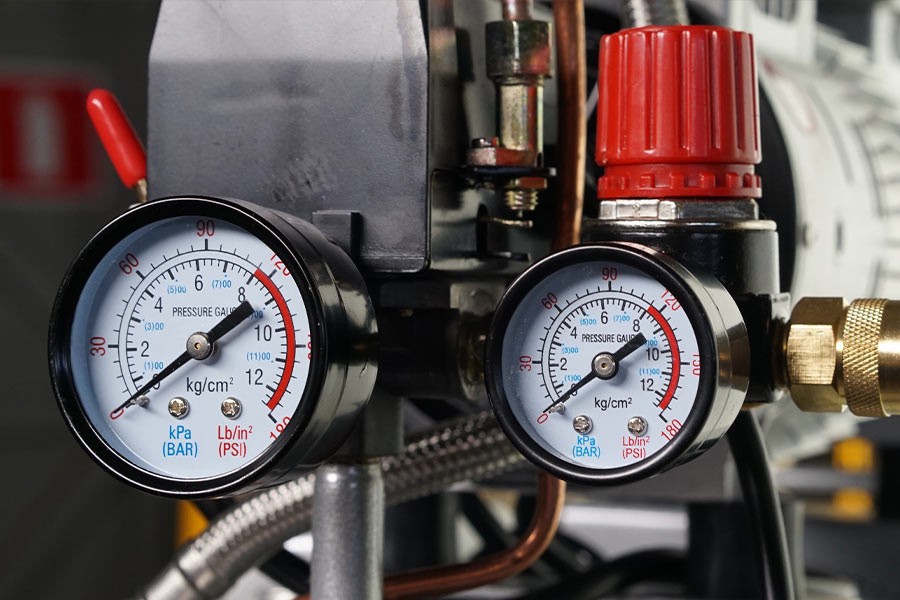

Pumps, compressors, and other rotating and moving equipment are often subject to strong vibrations, which not only damage the instrument but also cause errors. Vibration makes the reading of the pressure gauge difficult and may cause the pointer to deviate from zero. Using liquid-filled pressure gauges instead of dry pressure gauges can minimize these problems.

Glycerine-filled manometer and silicone-filled pressure gauge are two common liquid-filled pressure gauges.

So what is the difference between a glycerin-filled pressure gauge and a silicone oil-filled pressure gauge?

Glycerin: Glycerin is one of the commonly used liquids in liquid-filled level gauges. The pressure gauge filled with glycerin has a very high-cost performance and has a good damping effect in applications at room temperature. These pressure gauges work well at temperatures between -4°F and +140°F (-20°C and +60°C).

Silicone: Even at very low temperatures, silicone oil, and other comparable oils have lower viscosity; therefore, pressure gauges filled with silicone resin are more suitable for applications with large temperature changes, especially in colder climates As well as under conditions that may freeze. Their operating temperature ranges from -40°F to +140°F (-40°C to +60°C).