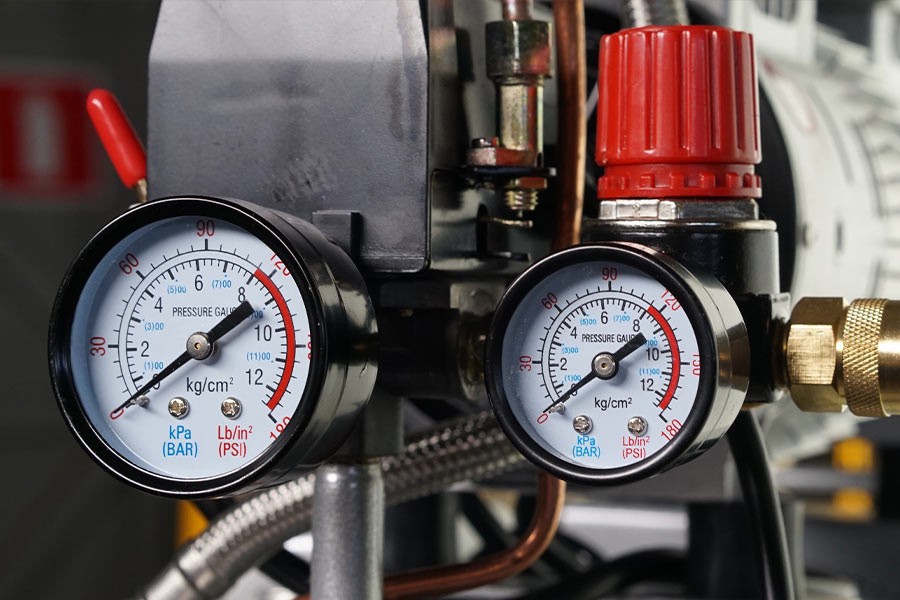

Pressure Gauge needs to be inspected by relevant national measurement units before installation, and relevant inspection certificates will be presented after passing the inspection. To ensure the qualification and accuracy of the Pressure Gauge, it can be determined according to the frequency of use. Generally, the measurement verification of the Pressure Gauge should not exceed 6 months, and the verification operation steps need to meet the following operations:

Perform metrological verification operations in accordance with the specifications: Verifiers can carry out Pressure Gauge metrological verification work through the rules and regulations of the elastic element type general Pressure Gauge, pressure vacuum gauge and vacuum gauge. According to the range of the pressure gauge to be inspected, the inspector needs to select the calibration instrument corresponding to the range, and at the same time check the validity period of the label of the standard table according to the specified inspection operation, so that the inspection work of the Pressure Gauge meets the verification requirements.

Install the calibration instrument according to the type of Pressure Gauge: When performing Pressure Gauge measurement, it is necessary to install the standard meter and the tested Pressure Gauge on the calibration instrument. If the tested Pressure Gauge is an oxygen-type oil-free Pressure Gauge, the tested Pressure Gauge needs to be installed on the oil-free joint that is connected to the oil-water separator, and the checker should be adjusted after the installation operation to make each part Able to be in a good state of verification.

Observe the temperature and humidity of the verification room: To ensure the accuracy of Pressure Gauge measurement verification, it is necessary to measure the temperature and humidity of the verification room before Pressure Gauge measurement verification to check whether the room temperature and humidity meet the specified operating limits.

Check whether the Pressure Gauge meets the operating requirements: During the measurement verification process of the Pressure Gauge, the appearance and internal parts of the Pressure Gauge should be inspected to see if it meets the operating requirements of the measurement verification, and after the inspection is completed, the corresponding test results are recorded.

Properly carry out the pressure gauge display value verification: For the measurement verification of the Pressure Gauge display value, the pressure rise and fall methods shall be verified according to the graduation line of the digital mark, and the stable and slow operation requirements shall be followed during the verification so that When the standard meter refers to the corresponding position, it can record the value of the inspected value accurately.

The standard method is adopted for measurement verification: the pressure gauge's indication value should be verified according to the 5/1 division value. During the verification process, the standard meter is verified according to the method of line reading, and the tested meter is verified by the method of estimated reading. For the errors generated in the verification process, it is necessary to carry out the error according to the specification and make relevant records after the error verification operation.

Cixi Oukate Instrument Technology Co., Ltd. is a pressure gauge manufacturer and gas test gauge and other products. Welcome to visit our official website.