- Home

-

Products

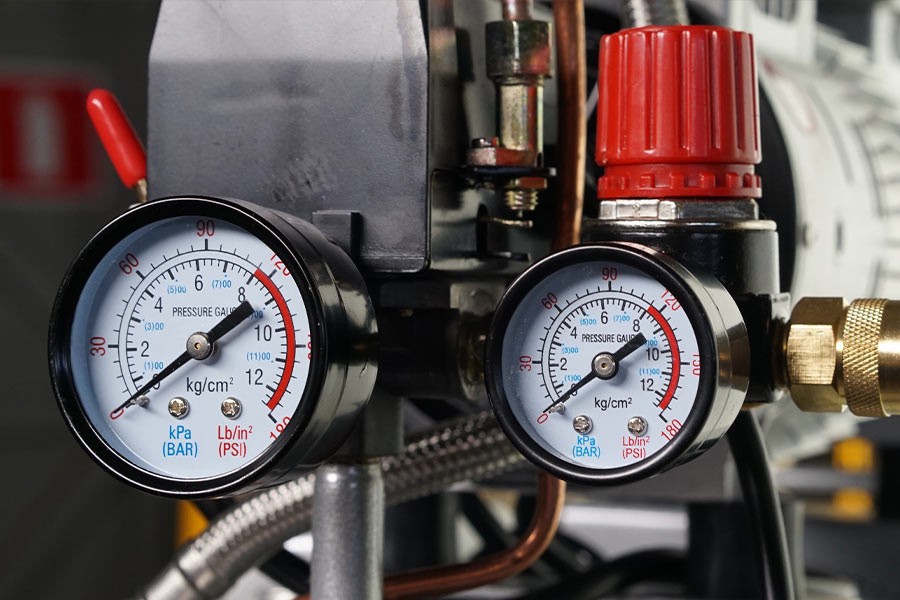

- All stainless steel pressure gauge

- Oil-Filled Gauge

- Ordinary pressure Gauge

- Stainless Steel pressure gauge

- Welding stainless steel pressure gauge

- Diaphragm pressure gauge

- Bellows pressure gauge

- Plastic case pressure gauge

- Tire pressure gauge

- Special pressure gauge

- Gas pressure gauge

- Temperature pressure gauge

- Small pressure gauge

- Oxygen pressure gauge

- Accessories

- Service&Support

- Company

- Media

- Contact