The vacuum pressure gauge is based on atmospheric pressure and is used to measure less than atmospheric pressure. The vacuum pressure gauge measures the negative pressure of liquids and gases that do not corrode steel, copper and copper alloys and do not crystallize and solidify without the danger of explosion. It is generally used in vacuum measurement of industrial processes such as petroleum, chemical industry, and metallurgy. So how does the vacuum pressure gauge read?

How to read the vacuum pressure gauge

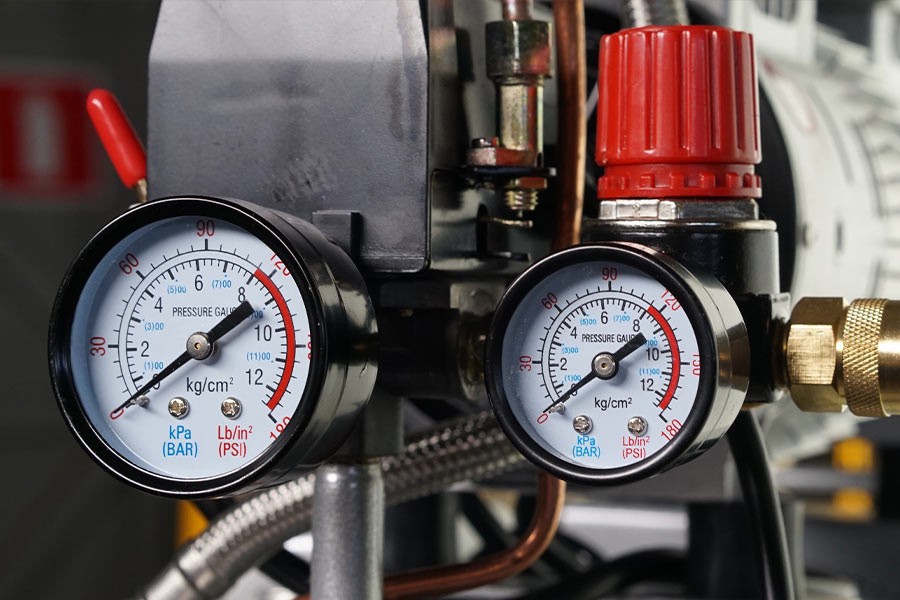

inHg is inches of mercury, the bar is a bar, MPa is megapascal 1MPa=145psi, PSI is pounds, the pressure is easier to understand by looking at MPa, R and numbers are the codes of the refrigerant gauge, and the pressure and temperature of the refrigerant pressure gauge have a certain correspondence relation. The number of kilograms of pressure that people often say in engineering refers to kg/cm2, while the pressure gauge is often marked with mpa. 1N/m2=1Pa, 1kg=9.8N, 1m2=10000cm2, so 1kg/cm2=98KPa=0.098MPa. In engineering, people approximately take 1MPa=10kg/cm2.

The range of the vacuum gauge starts from zero, while the range of the absolute pressure gauge starts from -1Bar. The pressure gauge is widely used in the transportation of gas and liquid. There is no danger of explosion, no crystals, no solidification and other pressure of the liquid, gas, steam and other media that the alloy does not corrode. It has the advantages of small size, safe and reliable performance, and clear display.

There are two ways of expressing pressure: one is the pressure expressed by absolute vacuum as the benchmark, called absolute pressure; the other is the pressure expressed by atmospheric pressure as the benchmark, called relative pressure. Since the pressure measured by most pressure measuring instruments is relative pressure, relative pressure is also called gauge pressure. When the absolute pressure is less than the atmospheric pressure, it can be expressed by the value of the absolute pressure in the container is less than one atmospheric pressure. It is called "vacuum degree".

Precautions for the use of vacuum pressure gauges

1. The meter must be vertical: use a 17mm wrench to tighten it during installation, and the case should not be twisted; collisions should be avoided during transportation;

2. The instrument should be used in the ambient temperature of -25~55℃;

3. The vibration frequency of the working environment is less than 25HZ, and the amplitude is not more than 1mm;

4. In use, due to the high ambient temperature, the indication value of the instrument does not return to zero or the indication value is out of tolerance, the sealing rubber plug on the upper part of the case can be cut off to make the inner cavity of the instrument communicate with the atmosphere;

5. The use range of the instrument should be between 1/3 and 2/3 of the upper limit;

6. When measuring corrosive media, media that may crystallize, and media with high viscosity, an isolation device should be added;

7. The instrument should be checked frequently (at least once every three months), and if any fault is found, it should be repaired in time;

Cixi Oukate Instrument Technology Co.,Ltd. not only has Vacuum pressure gauges but also Gas test gauges and other products, welcome to visit our official website.