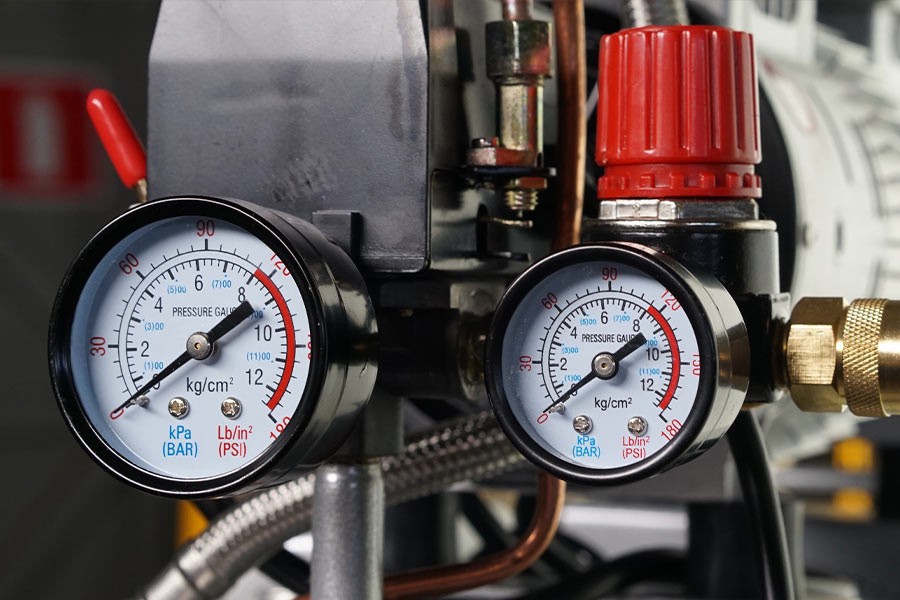

The glycerine-filled pressure gauge is usually better than the dry gauge for two reasons: performance and returns on investment. The glycerine-filled pressure gauge is filled with liquid, usually glycerin or silicone oil, designed to perform best under less than ideal conditions. Although WIKA’s liquid-filled pressure gauges are designed to work in harsh environments, they are also more economical in the long run: high heat, pulsation or vibration can cause instrument failure, but WIKA’s liquid-filled pressure gauges can withstand To adapt to these bad conditions.

Glycerine filled pressure gauge and traditional gauge

The main cause of instrument failure is vibration. In traditional dry-type meters, the precision connecting rods, pivots, and pinions are easily damaged by vibration, resulting in inconsistent performance. In a liquid-filled meter, the liquid filling effectively suppresses system pulsation and makes the meter pointer easier to read.

Likewise, humidity and moisture can cause problems for dry meters. Condensation can make the meter difficult to read, or in some cases, it can cause malfunction due to icing. However, liquid-filled meters are sealed to prevent internal condensation, and by keeping moisture out of the system, the movement of the meter can be protected under icing conditions.

The choice of filling fluid depends on the application, but glycerin is generally used for room temperature applications, while silicone oil is generally used for extreme temperature applications, especially when icing is a problem. If the system has exposed electrical contacts, an oil with insulating properties is ideal.

A gas test gauge is also our product, welcome to consult and purchase.